Boson Ressiliant Couplings is an amalgamation of the benefits of high power rating of gear coupling and flexibility of nylon or Rubber coupling with elevated evaluation. These are simple to maintain and install. The flexible grids are smoothly replacable with no disturbing connected drives. Boson Resellient Couplings are availabe in a wide range of sizes covering from 0.006 to 3.505 RMP/ HP with bores up to 265 mm.

Boson Ressiliant Couplings is an amalgamation of the benefits of high power rating of gear coupling and flexibility of nylon or Rubber coupling with elevated evaluation. These are simple to maintain and install. The flexible grids are smoothly replacable with no disturbing connected drives. Boson Resellient Couplings are availabe in a wide range of sizes covering from 0.006 to 3.505 RMP/ HP with bores up to 265 mm.

Features:

The features of Boson Resilient Couplings are as follows:

• Being all metal no chances for fast wearing.

• Dynamic balancing not reqd as all the parts are properly machined.

• Torsional flexibility is obvious. Gradual torsional flexibility offer protection for impact loadf ,shock load and vibration.

• As the grid springs are properly heat treated it may receive impact or shock loads without loosing of energy.

• During the transmission of full torque it also dampens the vibration even.

• At the time of overloads spring broken there by saving damage of main shaft and driven equipment.

• When amount of misalignment is more connected drives are protected by virtue of breaking of Grid or Teeth.

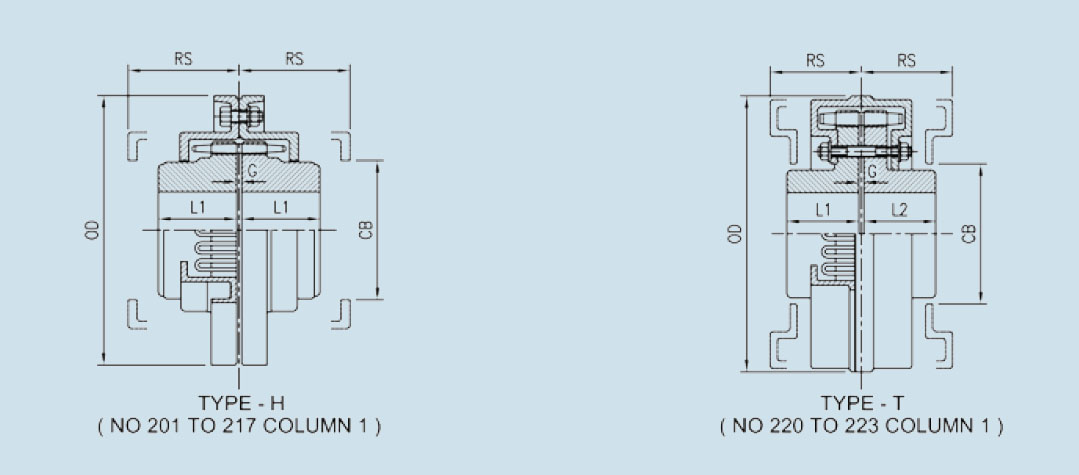

AVAILABLE IN TWO VARIANTS :

Horizontally Split Covers : Easy replacement and maintenance of grid.Ideal for tight space.

Vertically Split Sovers : Ideal for higher RPM.

SIMPLE AND EASY MAINTENANCE :

Very less components advantageous for easy maintenance.

Horizontally Split Covers

Horizontal covers are designed for ease of assembly and removal, particularly in tight spaces, as they can be put on after the hubs and grid spring element have been already assembled.

Horizontal covers are designed for ease of assembly and removal, particularly in tight spaces, as they can be put on after the hubs and grid spring element have been already assembled.

Vertically Split Sovers

Vertical split cover designs require putting the split covers on the shaft prior to putting on the shaft hubs and grid spring element. Once the hubs and grid spring element have been attached, the vertical split covers can then slid over the hubs and grid spring element and fastened together. (This also means that to completely remove a vertical split cover off a shaft, the grid spring element and coupling hubs would have to first be removed.)

Vertical split cover designs require putting the split covers on the shaft prior to putting on the shaft hubs and grid spring element. Once the hubs and grid spring element have been attached, the vertical split covers can then slid over the hubs and grid spring element and fastened together. (This also means that to completely remove a vertical split cover off a shaft, the grid spring element and coupling hubs would have to first be removed.)

The benefit of the vertical split cover design is that it can operate at a higher maximum speed (RPMs).. Based on your application, it may be required to go to a vertical split cover design if the horizontal cover design maximum speed is too low.

CONSTRUCTION:

Boson High torque Resilient Coupling having a grid spring which connects two hubs ,driving and driven. The spring is specially designed considering the requirement of the driving and driven equipments.

The Grooves on the hubs are little flared to allow the grid members to play during the torque transmitting.

The basic principle of design in Resilient Coupling, makes it capable to accommodate axial, parallel and angular misalignment between a driving and driven equipments.

BOSON RESILIENT COUPLINGS

Benefits:

1. Protection against misalignment : Parallel Axial Angular

2. Protection against Shock loads, Vibration & Thrust loads :

- All Metal Construction having no fast wearing out components

- Torsionally flexible Transmit full torque with dampened vibration and deduced peak load.

- Accommodates angular, parallel and axial misalignment.

- High ratings.

- Versatile design and interchangeability

- Easy assembly and maintenance

- Very low Downtime.

- Longer service life.

|

|

|

|

|

|

|

|

|

|

|

|