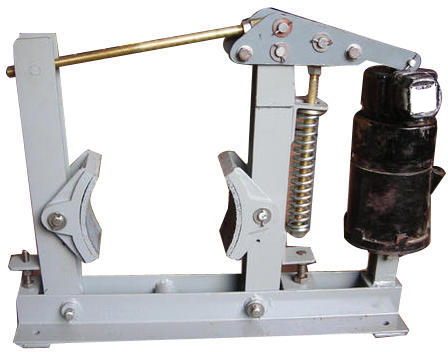

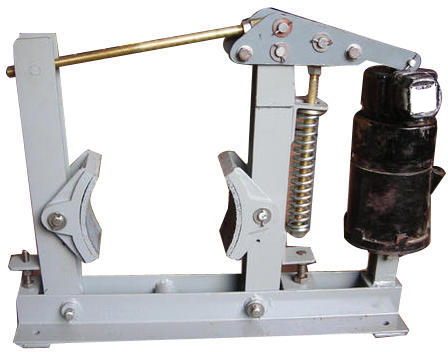

Boson Electro Hydraulic Thruster Brake

From 2002, Boson manufactures elctrohydraulic thrust brakes. Thousands of units are in hardest working condition in exploitation and environmental condition from tropical to polar.

Electrohydraulic thruster Brakes from Boson are reliable in nature and extremely compact designed. Oil is provided for immersion of electric motor. Periodically inclusion up to 2000 cycles per hour, with good cooling conditions provides long term of continuous work. This device is concepted in order to satisfy most advanced needs in stroke (50 – 60 mm), force (12- 400daN) and temperature range from 45 to + 45 degree C. We can also satisfy with special request for frequency, dimension, temperature and voltage. In standard execution is 380V is required.

There are many electrohydraulic thrusters brakes of different manufacturers in abroad and India. Boson produces special devices with same installation dimensions for substitutions.

On request of customers, the device can be equipped with indicator of releasing point. This indicator can be assembled outside and inside of device.

The main requirements of electrohydraulic thruster applications are fully reliable and high quality. All parts of products are fully tested. After assembling of working parameter, each product is tested and measured. These results are enclosed to delivered device and are computer processed.

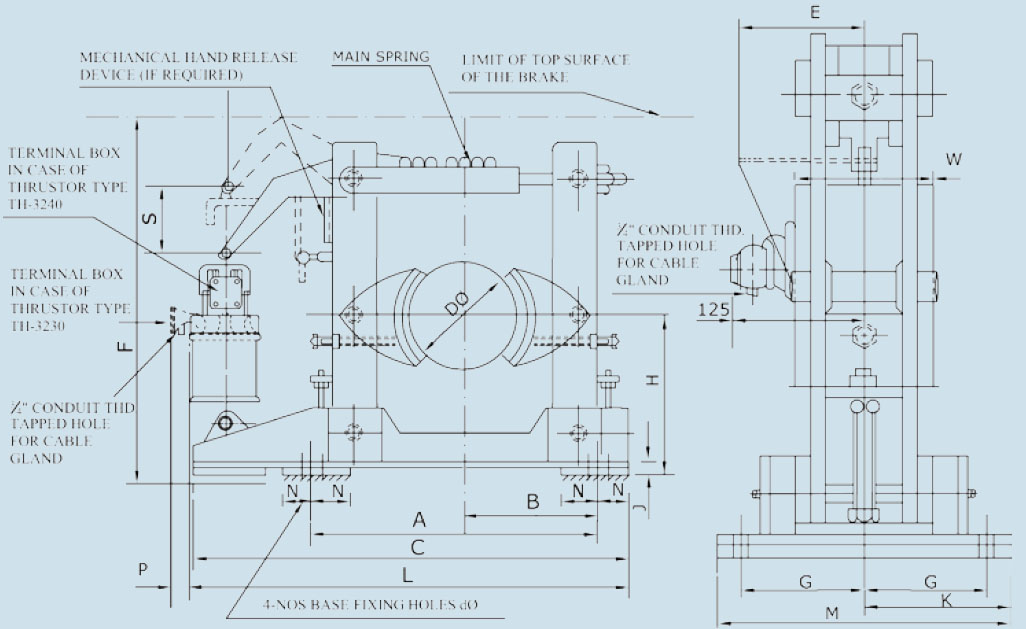

| Brake Type |

| 100 |

| 150 |

| 160 |

| 200 |

| 250 |

| 300 |

| 315 |

|

Thruster

Type |

| TH 3240 |

| TH 3240 |

| TH 3240 |

| TH 3240 |

| TH 3240 |

| TH 3240 |

| TH 3240 |

|

Drum

Ø In

mm |

| 100 |

| 150 |

| 160 |

| 200 |

| 250 |

| 300 |

| 315 |

|

Braking

Trq. In

Kgm. |

| 4.50 |

| 9 |

| 9 |

| 14 |

| 42 |

| 50 |

| 50 |

|

Brake

Shoe

Width |

| 60 |

| 70 |

| 70 |

| 100 |

| 100 |

| 125 |

| 140 |

|

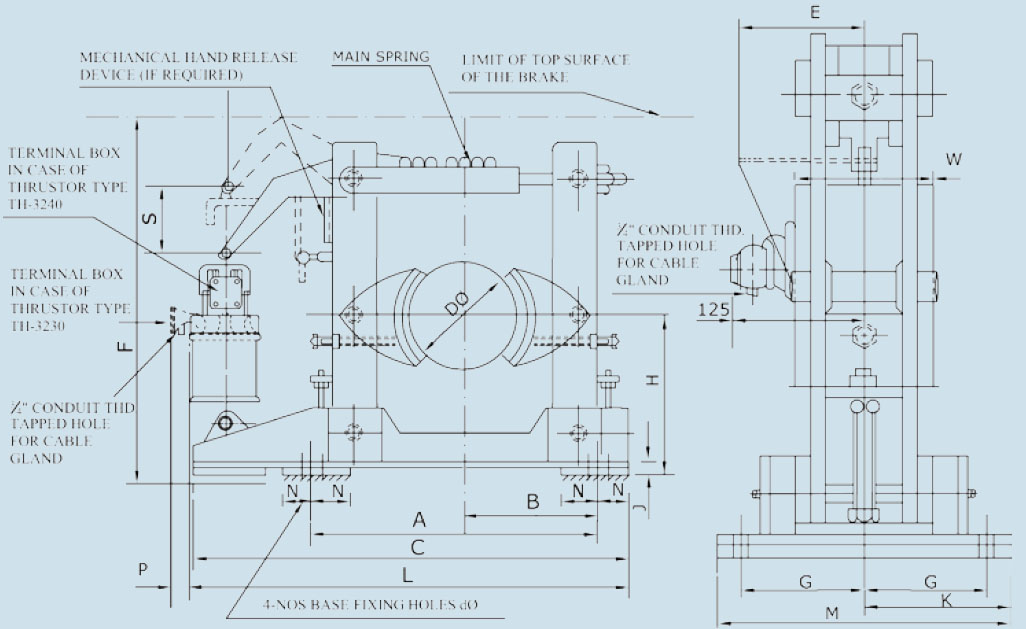

| A |

B |

C |

E |

F |

G |

H |

J |

K |

L |

M |

N |

P |

S |

DØ |

| 250 |

125 |

410 |

90 |

500 |

50 |

144 |

12 |

65 |

465 |

130 |

37.5 |

57 |

50 |

13 |

| 310 |

155 |

476 |

90 |

520 |

50 |

144 |

12 |

65 |

531 |

130 |

37.5 |

57 |

50 |

13 |

| 310 |

155 |

476 |

90 |

520 |

50 |

144 |

12 |

65 |

531 |

130 |

37.5 |

57 |

50 |

13 |

| 370 |

185 |

608 |

104 |

500 |

60 |

164 |

14 |

75 |

663 |

150 |

37.5 |

57 |

50 |

13 |

| 440 |

220 |

645 |

140 |

610 |

70 |

225 |

16 |

90 |

700 |

180 |

37.5 |

57 |

50 |

13 |

| 530 |

265 |

771 |

140 |

550 |

80 |

232 |

16 |

100 |

826 |

200 |

37.5 |

57 |

50 |

17 |

| 530 |

265 |

771 |

140 |

550 |

80 |

232 |

16 |

100 |

826 |

200 |

37.5 |

57 |

50 |

17 |

|

| Appx. Wt. In Kg. |

| 73 |

| 85 |

| 85 |

| 108 |

| 125 |

| 147 |

| 150 |

|

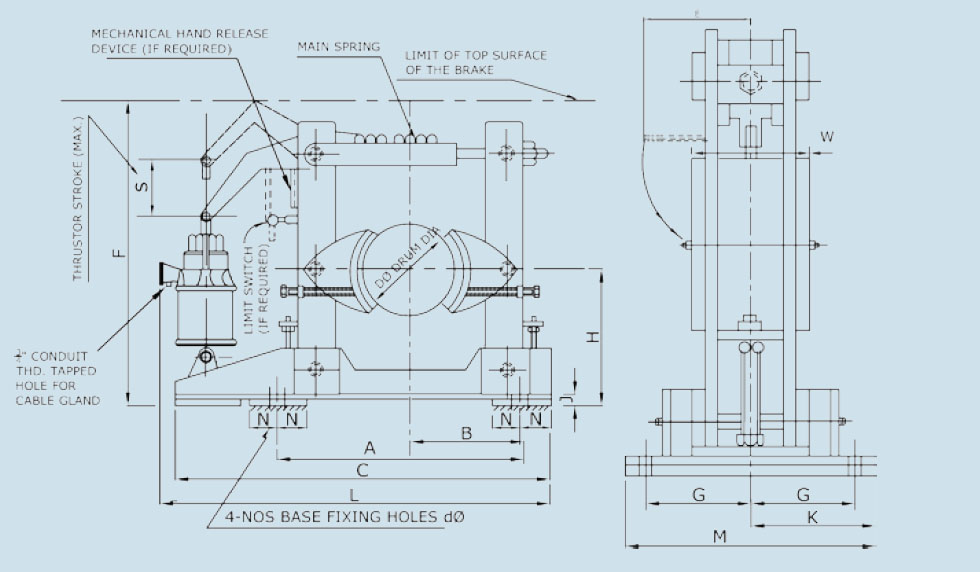

Size

BE-EHTB

3275 |

| 100 |

| 101 |

| 150 |

| 160 |

| 200 |

| 250 |

| 300 |

| 315 |

| 376 |

| 400 |

| 401 |

| 450 |

| 500 |

| 501 |

|

Thruster

Type |

| TH3275/TC |

| TH3275/TC |

| TH3275/TC |

| TH3275/TC |

| TH3275/TC |

| TH3275/TC |

| TH32100/TC |

| TH32100/TC |

| TH32120/TC |

| TH32120/TC |

| TH32121/TC |

| TH32121/TC |

| TH32120/TC |

| TH32121/TC |

|

Drum Ø

In mm |

| 100 |

| 100 |

| 150 |

| 160 |

| 200 |

| 250 |

| 300 |

| 315 |

| 376 |

| 400 |

| 400 |

| 450 |

| 500 |

| 500 |

|

Braking

Trq. In

Kgm. |

| 7.80 |

| 7.80 |

| 11.50 |

| 11.50 |

| 25.30 |

| 75.00 |

| 93.00 |

| 93.00 |

| 93.00 |

| 159.00 |

| 210.00 |

| 162.00 |

| 165.00 |

| 250.00 |

|

Brake

Shoe

Width |

| 60 |

| 60 |

| 70 |

| 70 |

| 100 |

| 100 |

| 125 |

| 140 |

| 160 |

| 150 |

| 150 |

| 200 |

| 200 |

| 200 |

|

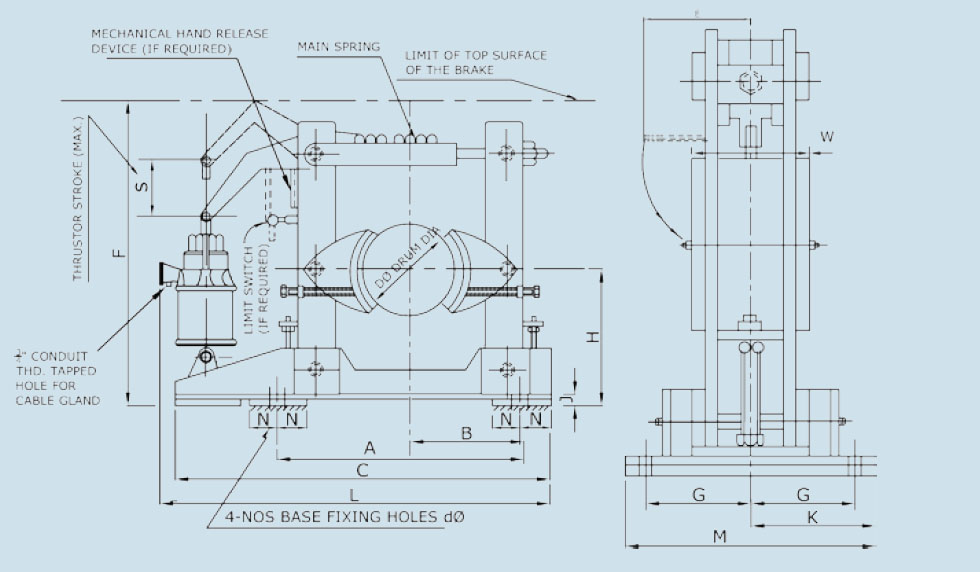

| A |

B |

C |

E |

F |

G |

H |

J |

K |

L |

M |

N |

S |

D |

| 250 |

125 |

410 |

90 |

563 |

50 |

144 |

12 |

65 |

522 |

130 |

37.5 |

50 |

13 |

| 250 |

125 |

410 |

90 |

400 |

50 |

100 |

12 |

65 |

522 |

130 |

37.5 |

50 |

13 |

| 310 |

155 |

476 |

90 |

600 |

50 |

144 |

12 |

65 |

588 |

130 |

37.5 |

50 |

13 |

| 310 |

155 |

476 |

90 |

600 |

50 |

144 |

12 |

65 |

500 |

130 |

37.5 |

50 |

13 |

| 370 |

185 |

608 |

104 |

578 |

60 |

164 |

14 |

75 |

720 |

150 |

37.5 |

50 |

13 |

| 440 |

220 |

645 |

140 |

605 |

70 |

225 |

16 |

90 |

757 |

180 |

37.5 |

50 |

13 |

| 530 |

265 |

771 |

140 |

572 |

80 |

232 |

16 |

100 |

883 |

200 |

37.5 |

50 |

17 |

| 530 |

265 |

771 |

140 |

572 |

80 |

232 |

16 |

100 |

883 |

200 |

37.5 |

50 |

17 |

| 616 |

300 |

875 |

140 |

662 |

100 |

288 |

16 |

125 |

987 |

200 |

37.5 |

70 |

17 |

| 640 |

320 |

900 |

140 |

673 |

100 |

300 |

16 |

125 |

1012 |

250 |

37.5 |

50 |

17 |

| 640 |

320 |

900 |

140 |

673 |

100 |

300 |

16 |

125 |

1012 |

250 |

37.5 |

50 |

17 |

| 740 |

370 |

1050 |

200 |

715 |

100 |

325 |

18 |

125 |

1087 |

250 |

40.0 |

75 |

18 |

| 740 |

370 |

1100 |

200 |

765 |

100 |

350 |

18 |

125 |

1137 |

250 |

60.0 |

75 |

18 |

| 740 |

370 |

1100 |

200 |

765 |

100 |

350 |

18 |

125 |

1137 |

250 |

60.0 |

75 |

18 |

|

Appx.

Wt. In Kg. |

| 73 |

| 73 |

| 85 |

| 85 |

| 108 |

| 125 |

| 147 |

| 150 |

| 220 |

| 236 |

| 236 |

| 295 |

| 315 |

| 315 |

|